Powerful lot query & reporting

Quickly trace lot history and movement with advanced queries.

Shelf-life and expiry date management

Automatically track shelf-life and expiry dates for compliance.

Home » 5 Supply Chain Strategies for Agile Procurement

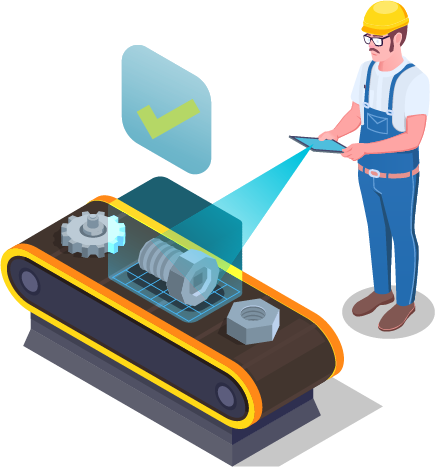

Traceability in manufacturing enables you to track materials and products through every stage—from raw inputs to final delivery. With SYSPRO ERP, you gain full supply chain traceability, empowering you to ensure compliance, improve quality, and act fast when issues arise.

Risk minimization in manufacturingSupply chains are vulnerable to disruptions, from faulty materials to supplier issues or regulatory breaches. SYSPRO ERP helps mitigate these risks by providing end-to-end visibility into material flow, production processes, and product history. With real-time traceability, manufacturers can detect and address issues early, preventing costly recalls, ensuring business continuity, and safeguarding the integrity of the entire supply chain. |

|

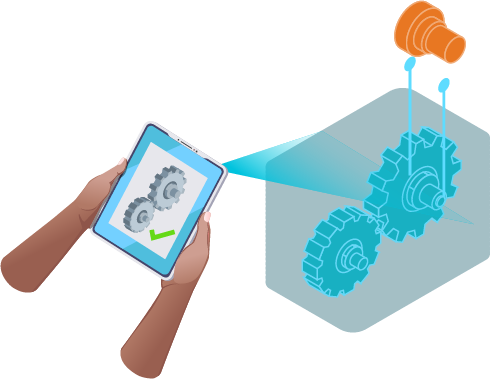

Proactive quality management with SYSPRO ERPMaintaining product quality across a multi-tier supply chain is a constant challenge. One weak link, be it a supplier’s raw material or a process deviation—can affect the entire output. SYSPRO ERP enables proactive quality management by linking traceability data with inspections, test results, and process controls. |  |

Mitigating recall risks through SYSPRO ERP’s TraceabilityIn complex supply chains, delays in responding to quality or safety issues can lead to widespread disruption and financial loss. Rapid recall is essential for minimizing that impact. With SYSPRO ERP’s traceability software, manufacturers can instantly identify affected lots, trace them across the supply chain, and initiate targeted recalls. |

|

Achieving global regulatory complianceGlobal supply chains must meet a growing list of industry and regional regulations, from FDA mandates to EU traceability laws. Non-compliance can lead to penalties, delays, and damaged relationships. SYSPRO ERP helps manufacturers stay compliant by capturing accurate, audit-ready traceability data at every supply chain stage. |  |

Your credibility, backed by SYSPRO ERP’s dataYour brand’s reputation is directly tied to supply chain reliability. SYSPRO ERP protects your brand through full, end-to-end traceability, allowing quick action during disruptions, verified ethical sourcing, and upheld quality promises. This transparency fosters crucial trust with customers and partners. By providing real-time access to product histories, certifications, and compliance data, SYSPRO ERP enables confident responses to all inquiries, reinforcing your credibility. |  |

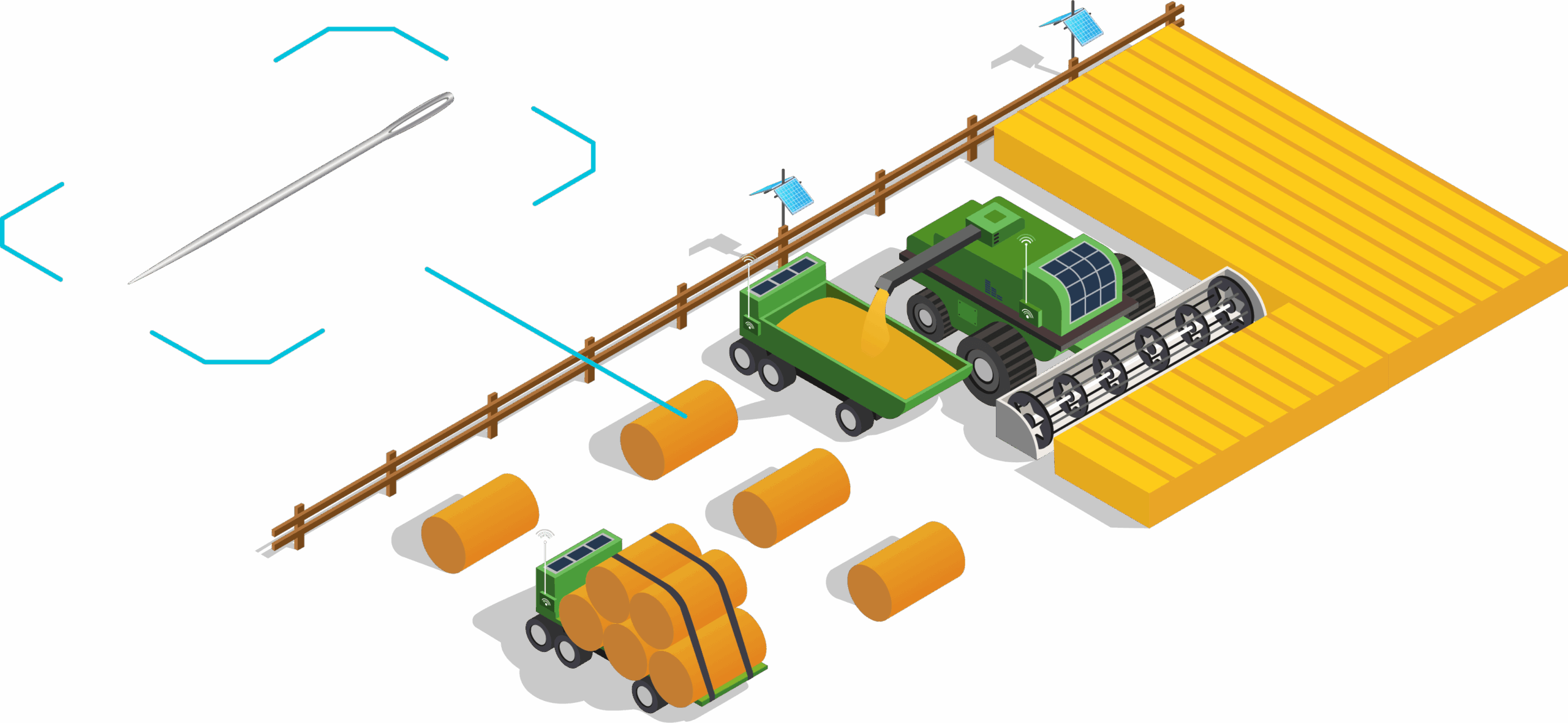

All departments feed traceability data into a centralized ERP system, tracking every product from supplier to customer with complete transaction history.

Connect raw materials to finished goods for bidirectional tracing—backward from issues to sources, or forward from suspect inputs to affected goods.

SYSPRO captures traceability events in real time through barcode scans, giving managers instant visibility into a product's entire journey for rapid, informed decision-making.

Built-in recall, quarantine, and quality control tools turn insights into action. SYSPRO isolates defects, automates holds, and notifies stakeholders to solve problems before they escalate.

Easily trace batches from suppliers to customers. Attach certificates, automate inspections, and prevent use of expired or non-compliant inventory—all within one system.

Quickly trace lot history and movement with advanced queries.

Automatically track shelf-life and expiry dates for compliance.

Link quality checks to lots for consistent standards and traceability.

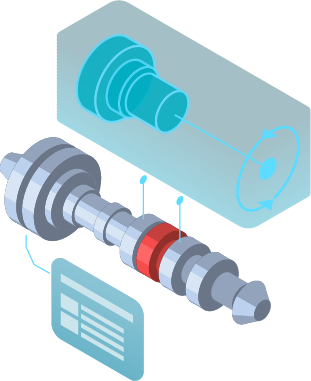

Track individual items with serial numbers for accurate traceability.

Enhance tracking with barcode and RFID for speed and accuracy.

Enable compliance by providing detailed audit ECC reports, audit trails and easily extracted mock recall reports for auditors.

An ERP system centrally manages all manufacturing data by assigning unique lot or serial numbers to materials and products at every stage, automatically capturing data as items move. Trace products both backward (to raw materials, suppliers, production processes, and quality checks) and forward (to finished goods, customers, and distribution).

Manufacturers should aim for certifications (e.g., ISO 9001/22000, GMP, FSSC) with traceable lot data, secure audit trails, and mock recall capabilities. Maintain audit readiness by retrieving any record in seconds and demonstrating end-to-end process control to auditors.

Manufacturers can absolutely get a significant ROI from implementing an end-to-end traceability system through their ERP.

The ROI comes from:

Here are four key technologies enabling modern supply chain tracking and transparency: