ERP with AI technology

Enhance your business operations using SYSPRO's ERP with AI technology

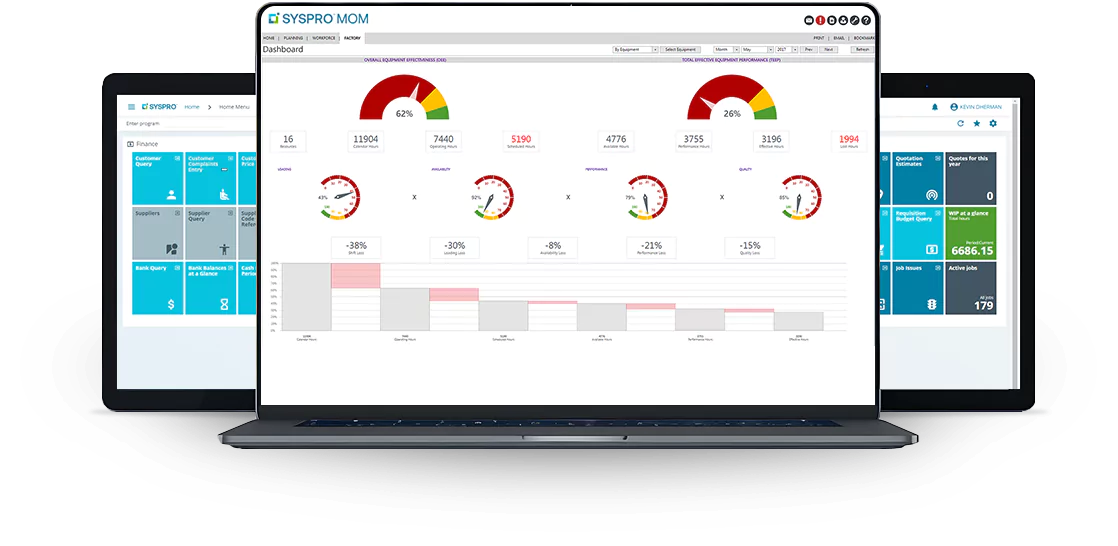

Advance your factory with Machine Learning

The increased usage of AI technology in smart sensors, devices, and machines enables smart, connected factories which improves business decision-making for manufacturers.

SYSPRO’s AI technology uses machine learning to deliver predictive analytics, detect anomalies in financial transactions, track supplier performance, and anticipate equipment issues to support preventive maintenance.

Watch the SYSPRO AI Demo

How can manufacturers use ERP with integrated AI capabilities

Manufacturers can leverage SYSPRO ERP with AI technology to optimise production processes, improve quality control, enhance decision-making, and boost overall efficiency. AI-driven insights enable predictive maintenance, supply chain optimisation, and real-time analytics, ultimately leading to increased profitability, improving work environments and customer satisfaction.

SYSPRO offers a scalable ERP solution with AI technology that is easy to adopt and integrate.

Centralize and analyze your organization's ERP data

Smart factories reduce unplanned downtime, improve product design, increase efficiency, and improve product quality and worker safety.

Key enablers of AI:

- Smart sensors - enables real-time data collection from production processes

- Internet of Things - manage large amounts of data from all aspects of production

- Cloud computing - enabling connections to store, access, and process data

How SYSPRO ERP integrates AI technology

Predictions

Use historical data to predict the future. Example: Predict when a customer might purchase a particular product or use historical data to predict when a customer might default on payments based on past behavior.

Anomaly detection

SYSPRO's AI engine monitors operator activity, flagging anomalies like unusually large transactions.

Example: A person, who typically processes $7,000 orders, suddenly enters a $100,000 order, the AI would alert relevant personnel to investigate potential fraud or error.

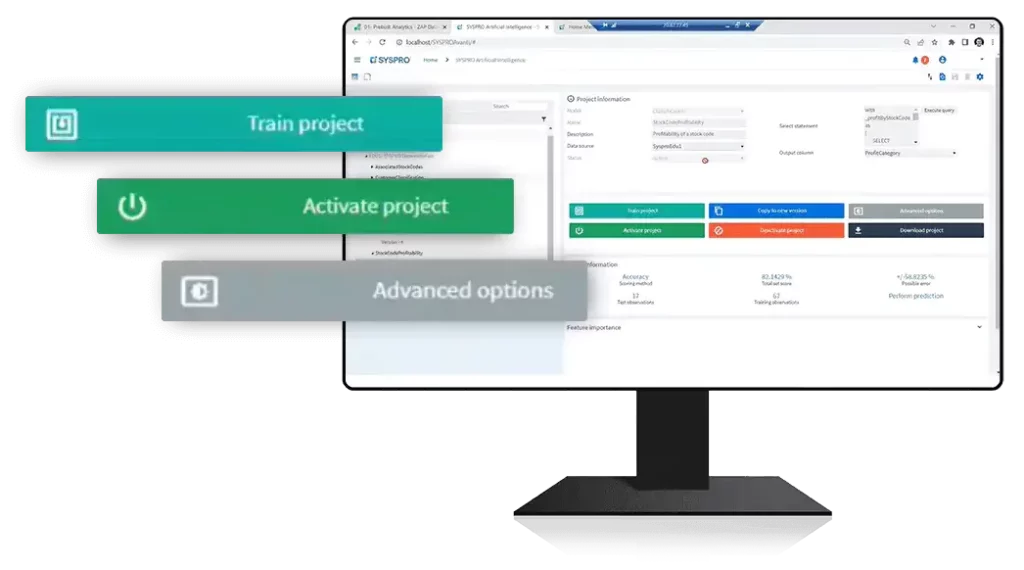

Machine Learning

Gain valuable insights from data, automate processes, and make data driven decisions by using machine learning algorithms.

Example: Machine learning analyses a sensors data from production equipment to predict potential failures, enabling proactive maintenance scheduling.

Additional practical applications of AI and Machine learning with SYSPRO include the following:

Supply chain management

Supply chain operations can be optimised by analysing historical data on inventory levels, demand patterns, transportation costs, and supplier performance. AI can alert procurement teams to potential supplier issues, eliminating the need for manual report generation and searching.

Customer account management

Streamline account management by automatically detecting trends and anomalies. Example: AI can analyze sales, returns, and credit data to identify potential issues or opportunities.

Finance

Cash flow prediction can help businesses anticipate payment delays.

ML can also identify anomalous financial transactions identifying fraud or human error.

Example: a CFO could receive early warnings about potential 60-day payment delays, allowing them to adjust purchasing and supplier payments accordingly.

Demand forecasting

Analyse historical sales data, market trends, and external factors to generate accurate demand forecasts. This helps manufacturers optimise production planning, reduce costs, and improve customer satisfaction by ensuring product availability.

Discover how SYSPRO's machine learning capabilities can take your business to the Next Level.

Benefits of SYSPRO ERP AI technology

- Optimize resource planning with job status predictions

- Plan to recover lost sales by understanding why they happen

- Enhance customer satisfaction by reducing sales order issues

- Boost revenue with accurate sales forecasting

- Maximize inventory profitability with stock code profitability predictions

- Enhance cash flow with AP invoice payment predictions

- Intelligent customer classification to maximize customer profitability

- Prevent sales order errors with sales order line anomaly detection

- Reduce procurement risks with purchase order line anomaly detection

- Supplier performance insights enhances supply chain reliability

FAQs

Artificial Intelligence in Enterprise Resource Planning (ERP) systems is transforming business operations through intelligent automation, predictive analytics, and machine learning capabilities. Modern AI-powered ERP solutions streamline workflows, automate routine tasks, provide real-time insights for better decision-making, and optimize resource allocation across departments, ultimately driving efficiency and competitive advantage in today’s digital marketplace.

Your business should consider implementing AI-enabled ERP if you’re experiencing challenges with manual data processing, struggling with accurate forecasting, or seeking to optimize operations and reduce costs. Organizations handling large amounts of data, managing complex supply chains, or looking to scale operations efficiently will particularly benefit from AI-enhanced ERP systems that can automate processes and provide predictive insights.

Start by identifying specific areas where AI can add immediate value, such as quality control, predictive maintenance, or inventory management. Begin with a pilot project in one department, ensure proper staff training, and gradually expand successful implementations across your organization while working with experienced vendors who understand both manufacturing processes and AI technology.