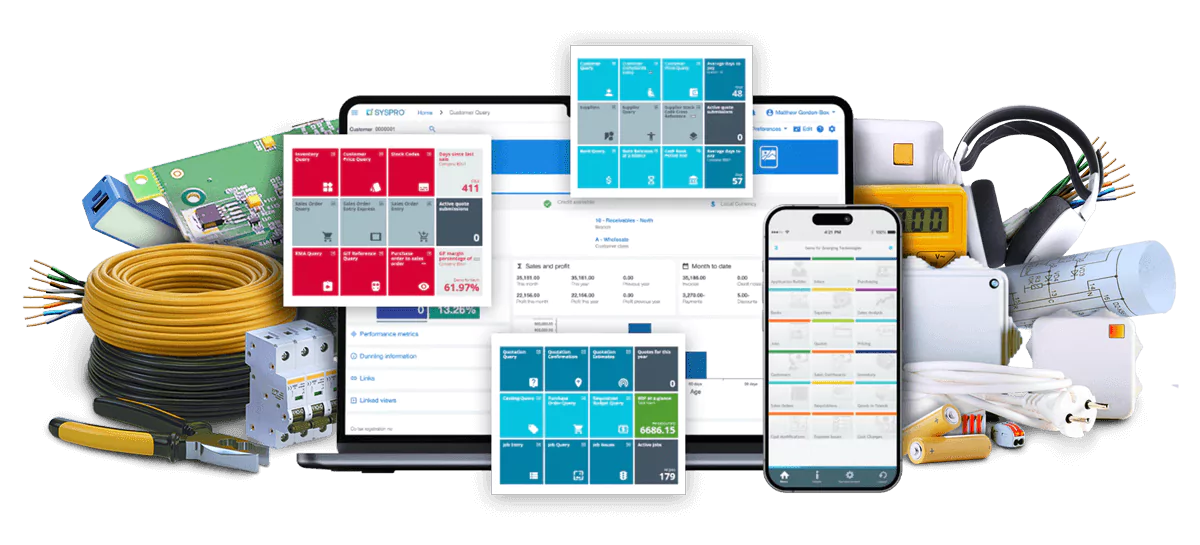

Supply chain optimization

SYSPRO enables real-time component tracking, supplier management, and demand forecasting to minimize disruptions and ensure timely delivery.

Increased profitability

SYSPRO's detailed costing and analytics tools help optimize resource allocation, reduce waste, and improve overall profitability across your electronics manufacturing operations.

Improved inventory management

Maintain optimal inventory levels for electronic components production with SYSPRO's advanced forecasting and stock management capabilities.

Quality control & compliance

Meet industry standards with SYSPRO's quality management system. Track and trace components to ensure compliance and exceptional products.

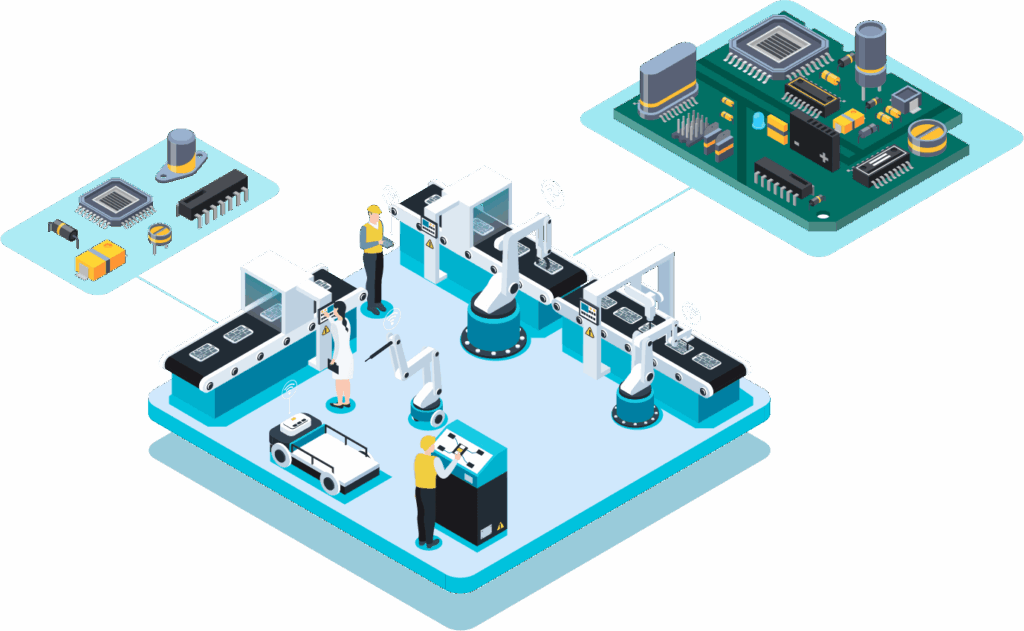

Streamlined production planning

Optimize production and resources with SYSPRO's scheduling tools. Boost throughput and cut lead times in electronics manufacturing factory.

Manufacturing operations management

Get real-time insights into manufacturing with SYSPRO. Connect production to management for data-driven efficiency and fewer bottlenecks.