MRP system benefits for your manufacturing organization

Improve management

Manage your full business across multiple warehouses

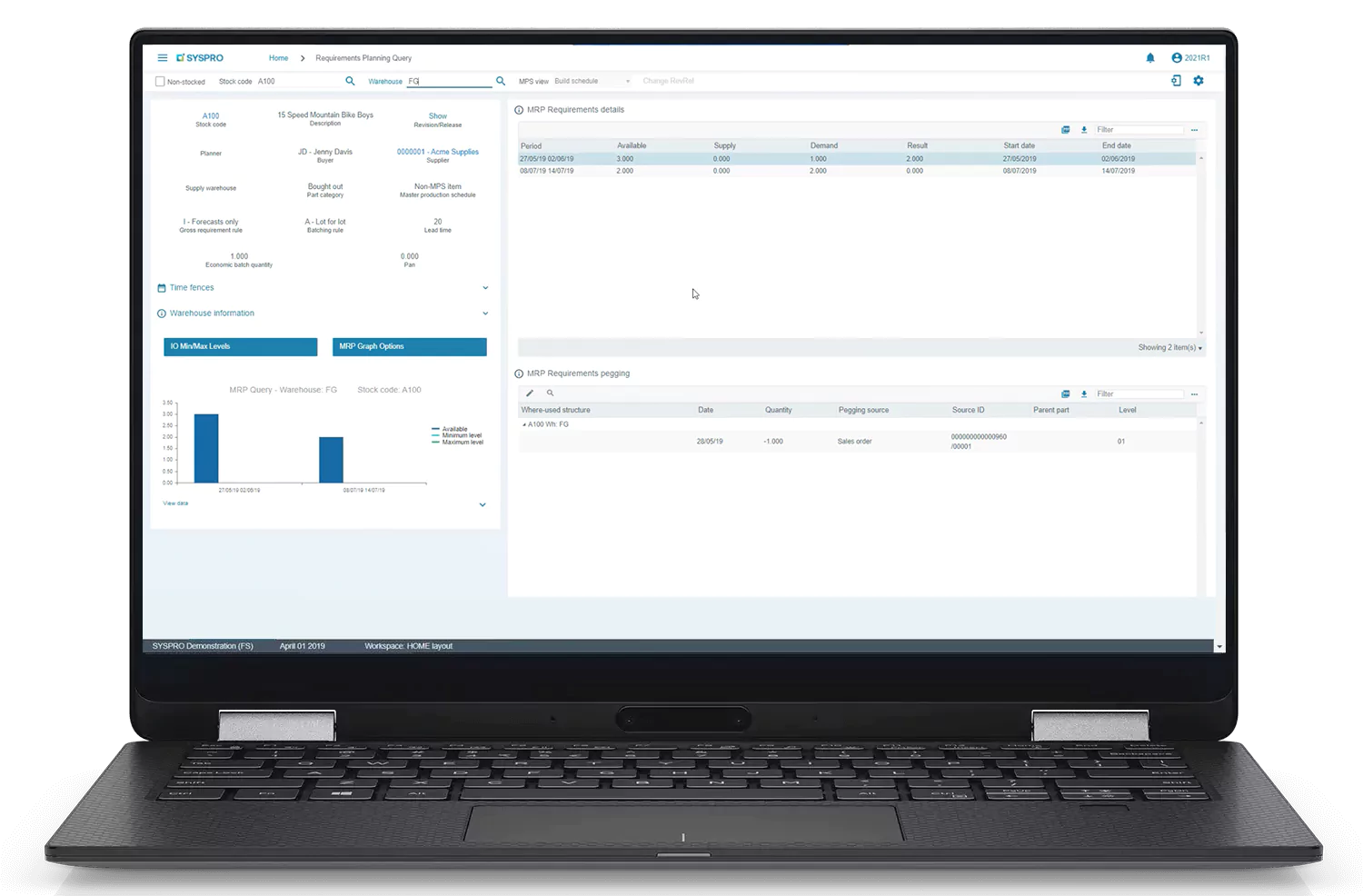

Effective planning

Planning of material and production with resource queries

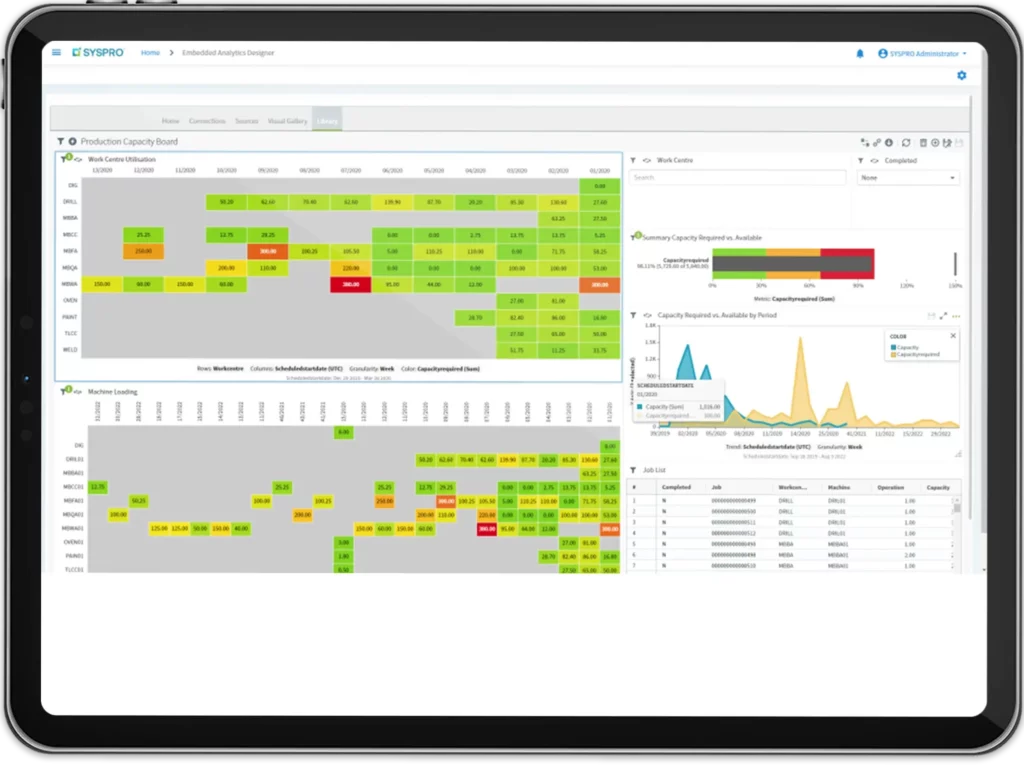

Capacity planning

Identification of critical resources with capacity planning

Queries & reports

Detailed pegging information available in queries and reports

Bucketless system

Provides the facilities to run 'what-if' scenarios.